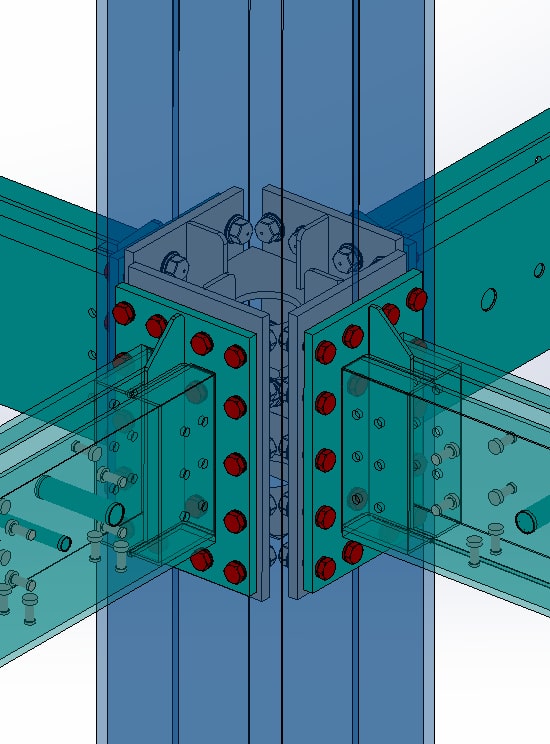

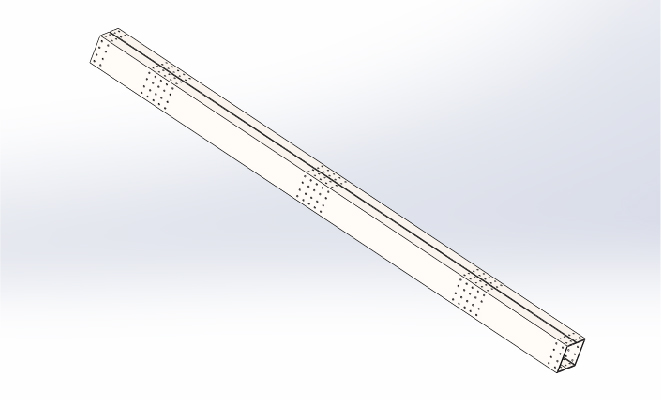

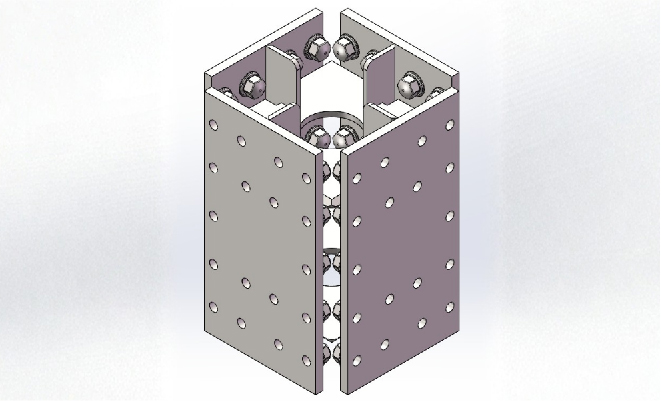

An innovative joint form was prefabricated and precisely placed inside the column during fabrication.

Main features:

we deliver complete one-stop solutions from design to production to on-site assembly, enabling truly efficient and modern construction.

Driven by associated factors to build a strong supply chain, we deliver efficient, modern construction that serves consistent customer acclaim.

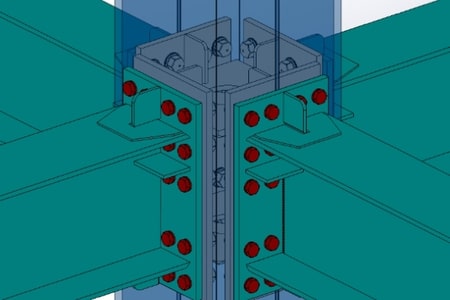

No on-site welding, only bolt-screwing

No technical workers needed

Everyone can learn to install within 2 minutes

Laboratory tested and real-world proven Handed years of life-expectancy coping with extreme circumstances.

Standard and homogenous components transport to the world at a low cost.

Standard joint built-in column, achieving blind bolt connection for closed section

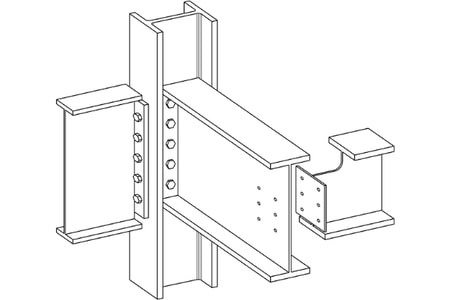

Specialized joint type for different scenario, can not achieve blind-bolt connection Irregular components

Standard joint, column and beam enabling intelligence massive production

Irregular column and beam strongly depend on skilled workers

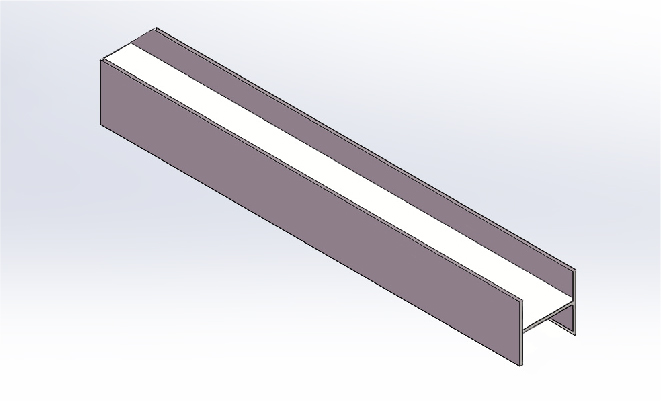

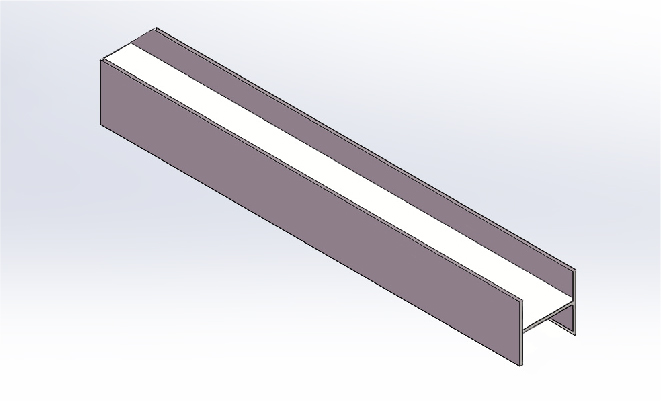

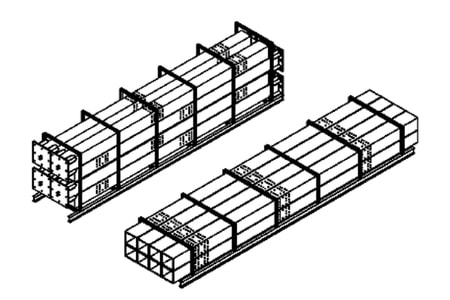

No end-plates, corbels or irregular shapes, full space-utilization for containers.

Global transportation cost reduce by more than 50%

_1768612757_WNo_450d300.jpg)

Corbels, end plates and irregular shapes on components, high transportation cost

No on-site welding and no technical workers needed

Modular erection reducing the time working-at-height by 60%

_1768612777_WNo_450d300.jpg)

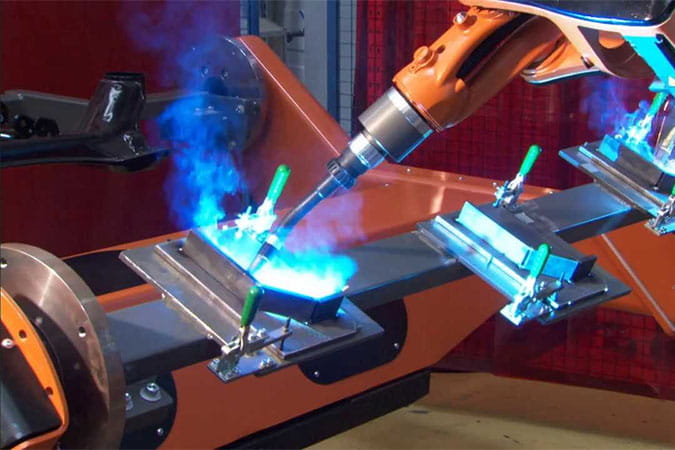

Might still need little on-site welding for side plate, and technical workers needed

Safety risks for working at height

No on-site painting, anti-rust and fire-resistant treatment fully prefabricated

_1768612797_WNo_450d300.jpg)

On-site fire-resistant painting, on-site labor-intensive and air pollution