Optimize your industrial operations with our prefabricated steel and modular buildings. Engineered for warehouses, light factories, manufacturing facilities, and logistic centers, our industrial prefabricated solutions ensure rapid on-site assembly, durable structural performance, and flexible layouts tailored to operational needs. From design and production to installation, we provide end-to-end support for safe, efficient, and cost-effective industrial construction.

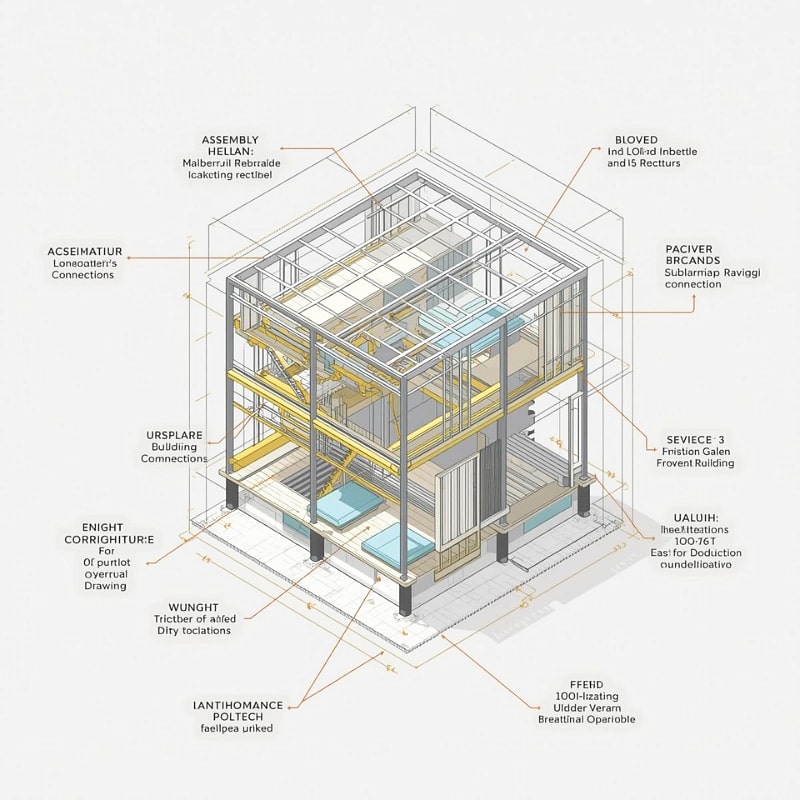

Prefabricated industrial buildings are purpose-built modular structures designed for warehouses, factories, logistic centers, and light manufacturing facilities. Constructed from factory-fabricated steel and panel units, these buildings enable rapid on-site assembly while maintaining high structural performance and long-term durability. They are ideal for industrial projects where efficiency, flexibility, and safety are critical.

S-CAS prioritizes prefabricated construction using modern methods, offering a significant speedup and improvement in construction accuracy compared to precast and cast-in-place concrete. Furthermore, it offers the following advantages:

S-CAS is 75% lighter than reinforced concrete, increases live load capacity, and is typically between 1 and 3 inches thick.

Contact AkoetechCCP wall panels are used as exterior wall panels, interior wall panels, floor panels, roof panels, and floor slabs, allowing for seamless construction of houses.

Compared with traditional cast-in-place construction, our low-rise prefabricated building system reduces overall construction time by over 40%, while maintaining high structural strength, durability, and long-term performance.

Get a Quote Now

Engineered modular buildings for warehouses, factories, logistic centers, and light industrial facilities, combining efficiency, safety, and scalability

Prefabricated industrial warehouses designed for storage and logistics, offering 2–5 floors with flexible modular layouts and rapid assembly.

Modular industrial buildings for light manufacturing, providing 2–4 floors with high load capacity, adaptable layouts, and quick construction timelines.

Prefabricated multi-story logistic centers engineered for efficient material handling, offering 3–6 floors and modular bays to scale operations quickly.

Prefabricated industrial modules for temporary production lines, construction sites, or emergency storage, designed for fast assembly and structural safety.

Notes: Due to confidentiality agreements with our clients on most building projects, we are only able to showcase a selected number of low-rise prefabricated building designs. All displayed projects have been shared with full consent from our clients.

Low-cost worldwide shipping, 10-minute installation by anyone, rapid mass production capability

As a trusted provider of industrial prefabricated building systems, we offer end-to-end solutions from structural design to modular manufacturing and on-site installation. Partnering with us ensures faster deployment, cost efficiency, and robust structural performance for warehouses, factories, and logistic hubs.

Our industrial prefabricated solutions include high-strength walls, floor slabs, roof panels, and structural frames designed for seamless multi-story industrial assembly.

Factory-made modules minimize on-site labor and allow assembly of multiple floors quickly, reducing construction timelines for warehouses and factories by up to 40–50%.

Engineered for industrial loads, our prefabricated systems meet stringent standards for seismic and live loads, ensuring stability, safety, and longevity under heavy operational conditions.

Modular production reduces material waste, labor demand, and on-site uncertainties, optimizing budgets for multi-story industrial buildings.

Modular units can be combined for varied layouts, expanded vertically or horizontally, and customized for specific industrial applications like storage, production, or logistics.

Our industrial prefabricated projects have been successfully delivered worldwide, meeting international building codes and supporting large-scale multi-story industrial operations.

Find the best solution for your project and check our detailed pricing table for guidance.

_1772095648_WNo_900d599.jpg)

_1772095905_WNo_900d600.jpg)

_1772096016_WNo_900d599.jpg)

_1772096217_WNo_900d599.jpg)

| For typical outdoor piper racks | Conventional welded steel pipe racks | Conventional bolted steel pipe racks | Modular steel pipe racks | S-CAS bolted steel pipe racks | |

| Construction Period | 100% | 80% | 60% | 30% | |

| Overall cost | 100% | 105% | 124% | 100% | |

| Cost break down | Manufacturing cost |

42% (Primer) |

64% (Primer, intermediate coat and topcoat) |

88% (Primer, intermediate coat and topcoat) |

72% (Powder coating integrating anti-corrosive and 2-hour-fire-resistance) |

| On-site painting cost |

16% (On-site intermediate coat and topcoat) |

9% (on-site partial repaint) |

6% (on-site partial repaint at the joint spots) |

2% (on-site partial repaint) |

|

| On-site installation cost |

42% (Welding cost) |

37% (Bolt connection) |

56% (Modular installation) |

26% (Bolt connection) |

|

| Coating service life | 3-5 years | 5-7 years | 5-7 years | 25-30 years | |

| Maintanance cost for future 30 years | 100% | 50% | 50% | 0%-2% | |

Industrial prefabricated buildings are typically designed for 2–6 floors, depending on the operational requirements and structural load. Advanced engineering allows some multi-level warehouses or factories to reach up to 8 floors while maintaining safety and efficiency.

Absolutely. These structures are engineered for durability under industrial conditions. With proper design and installation, their service life can exceed 50 years, supporting heavy equipment and high operational loads.

Factory-made modules minimize on-site labor and assembly time. Structural installation can progress at 1–2 floors per week, reducing overall construction timelines by up to 40% compared with conventional methods.

Yes. Industrial modules can include pre-installed conduits, piping routes, and reserved openings for machinery, ventilation, and utilities, minimizing on-site errors and accelerating operational readiness.

Certainly. Floor plans, ceiling heights, column spacing, and facade configurations can be tailored to specific operational needs, code requirements, and local environmental conditions.

While prefabricated industrial buildings may have slightly higher material costs, overall project expenses are often lower due to reduced labor, shorter timelines, and minimized on-site disruptions.

Foundations typically include reinforced concrete raft slabs or pile-supported footings, depending on soil conditions and operational loads. Structural engineers determine the appropriate foundation for each project.

Yes. The modular design allows for horizontal or vertical expansion, interior adjustments, or functional upgrades with minimal impact on ongoing operations.

Properly engineered industrial prefabricated buildings comply with regional seismic and wind load standards. Structural calculations are adapted to ensure operational safety and stability under extreme conditions.

Yes. We provide detailed structural drawings, assembly manuals, and remote or on-site support to ensure accurate installation and smooth operational start-up for industrial prefabricated buildings.